Baoshan Iron & Steel Co., Ltd. (Baosteel) is a world-leading integrated steel enterprise and core subsidiary of China Baowu Steel Group—a Fortune Global 500 company. Listed on Shanghai Stock Exchange (SSE: 600019), Baosteel operates major production bases in Baoshan (Shanghai), Meishan (Nanjing), Zhanjiang, and Qingshan (Wuhan) after merging with Wuhan Steel in February 2017. It ranks second globally in crude steel output, third in automotive sheet production, and first in grain-oriented electrical steel among listed steelmakers, offering the world's most comprehensive carbon steel product portfolio.

Baosteel pursues an innovative, green, and open development strategy. With globally recognized brands and cutting-edge technologies, it has established worldwide marketing and processing networks. Its proprietary advanced products—including next-gen automotive AHSS, electrical steels, premium home appliance steels, OCTG pipelines, bridge steels, and hot-rolled heavy rails—meet international benchmarks. The company strives to become the "world's most competitive steel enterprise" and "most investable listed company".

As China's largest steel producer, China Baowu has significantly contributed to Shanghai's socioeconomic development. It is transitioning from manufacturing to services, from steel to advanced materials, and from domestic to global operations—aligning with Shanghai's "Five Centers" development strategy. Since 2012, Baowu's Shanghai operations have achieved:

· 5.93 million-ton reduction in ironmaking capacity

· 7.5 million-ton reduction in steelmaking capacity

· Energy savings equivalent to 4.71 million tonnes of standard coal

· 2,054-ton SO₂ reduction

· 296-ton COD reduction

Exceeding national industrial restructuring targets.

Baosteel's Baoshan ironmaking plant—operating at global environmental standards—initiated desulfurization upgrades to minimize ecological impact. Accessen secured this contract through proven equipment reliability and service efficiency. Since 2007, Accessen has supplied nearly 100 heat exchangers for critical projects including Zhanjiang blast furnaces and desalination plants. The Zhanjiang Steel Base project won FIDIC's "Outstanding Project Award" in 2018—the only Chinese industrial project so honored. Accessen's heat exchangers for blast furnace cooling and desalination systems maintain optimal performance to date.

Technical Application:

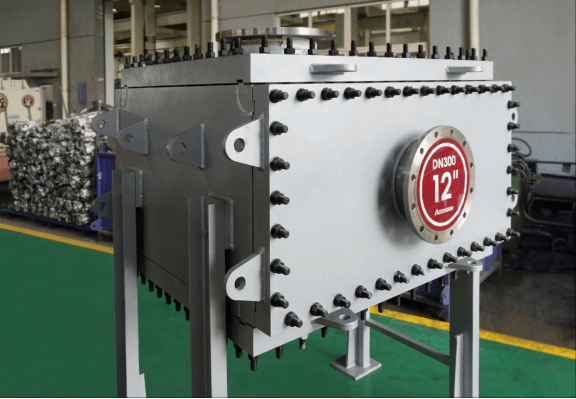

A-BLOC four-side accessible welded exchangers cool desulfurization fluid with circulating water in Baosteel's coal chemical Phase IV project. Key advantages:

· Corrosion-resistant square plate packs enable maintenance access

· Fully automated welding ensures structural integrity

· True counter-flow design (vs. semi-counterflow in conventional units) enhances turbulence

· 4× higher heat transfer coefficient than shell-and-tube exchangers

· Compact footprint with minimal approach temperature

· Free-expansion frame absorbs thermal stress, extending service life under thermal shock conditions

Case Overview

Baoshan Iron & Steel Co., Ltd. (Baosteel), a core subsidiary of Fortune Global 500 company China Baowu Steel Group, is a world-leading integrated steel producer. Listed on Shanghai Stock Exchange (SSE: 600019), it operates major manufacturing bases in Baoshan, Meishan, Zhanjiang, and Qingshan following its 2017 merger with Wuhan Steel. Baosteel ranks second in global crude steel output, third in automotive sheet production, and first in grain-oriented electrical steel among listed steel enterprises, offering the industry's most comprehensive carbon steel portfolio.

Location: Baoshan, Shanghai

Timeline: November 2018

Key Highlights:

· A-BLOC four-side accessible welded heat exchanger

· True counter-flow heat transfer

· Seawater desalination application

· FIDIC (International Federation of Consulting Engineers)

· FIDIC "Outstanding Project Award"

· Desulfurization fluid cooling system

Product Deployed:

A-BLOC 1 set