Located in the High-Tech Development Zone of Changshu, the GLP Data Center Campus is built to the highest national Class A standards, with a core focus on high reliability and high-performance services. Designed to serve global clients in finance, insurance, internet, and government sectors with substantial data capacity, it provides comprehensive services including server hosting, leasing, pipeline value-added solutions, and leading data support for internet enterprises and hyperscale customers.

The campus spans a total floor area of approximately 62,509 square meters, with an IT load of 120MW. Developed in three phases and officially operational in 2024, it houses 8,152 units of 81kW cabinets, 8 units of 16kW network core cabinets, and 18 carrier cabinets – totaling 8,178 cabinets. The project has received dual 5A certifications in Green Data Center planning and operation, as well as the LEED Gold certification.

GLP Data Centers currently provide 1,400MW of IT load globally, with a total planned capacity of 2,900MW. Twelve data centers are already in operation, delivering over 320MW of IT load. Through elastic and efficient intelligent computing innovations, rapid deployment capabilities, and smart low-carbon operations, GLP has become a high-standard green computing infrastructure provider, strongly supporting the computing power expansion of enterprise clients and large-scale cloud service providers. It was recognized as one of China’s Top 10 Computing Power Center Service Providers in 2024.

Phase III – Advancing Reliability and Adaptability

Phase III continues to emphasize high reliability and high-performance services, delivering leading data support for internet companies and hyperscale users. It features an elastic and adaptive infrastructure architecture that flexibly accommodates power densities ranging from 8–15kW. A customized power supply and distribution solution was implemented, upgrading the cabinet-level power architecture from traditional 2N to a Distributed Redundancy (DR) design, enhancing power supply reliability and ensuring secure operation of computing servers.

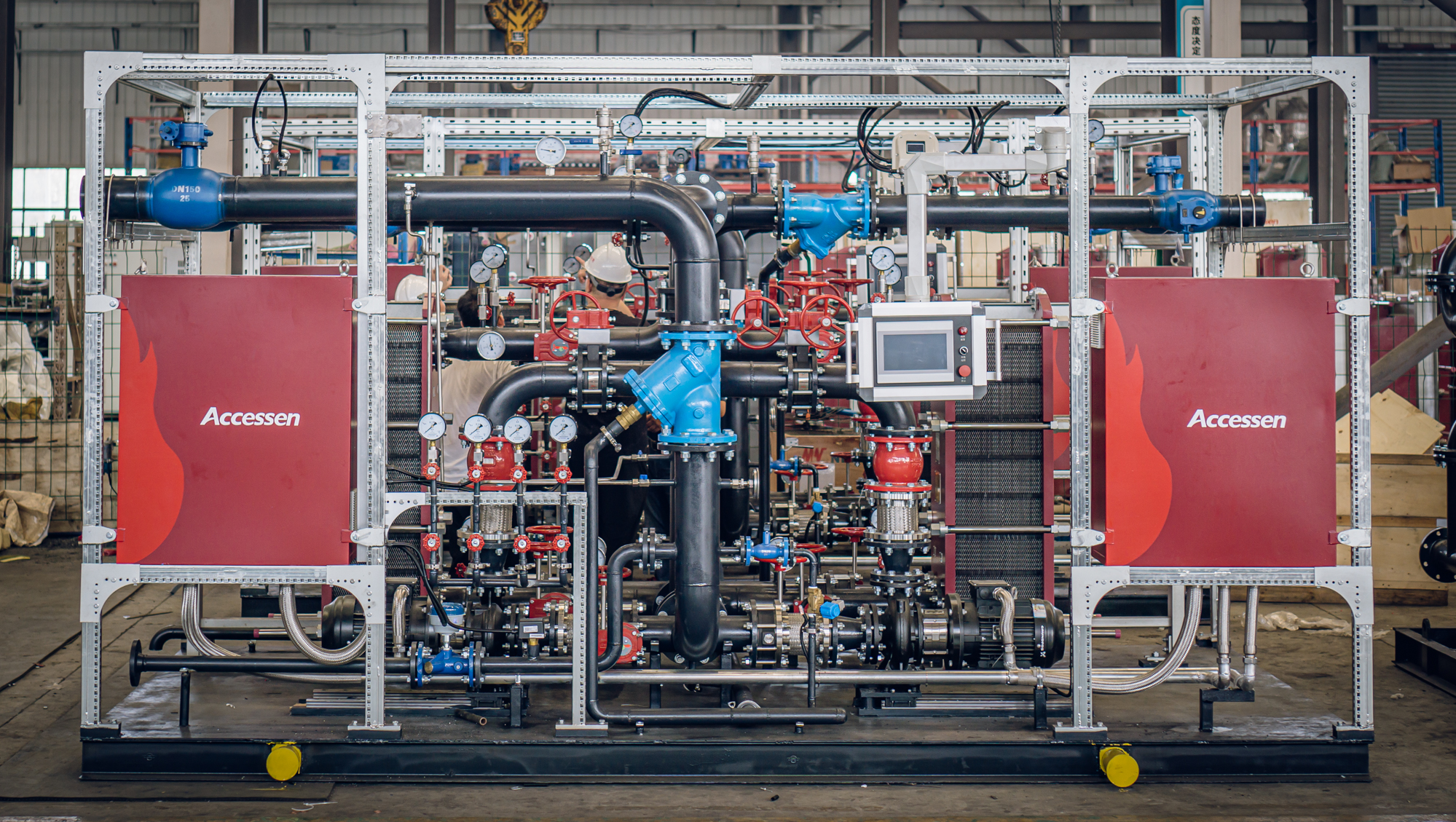

Building on the successful indoor prefabricated solutions of Phases I and II, Phase III further innovates by utilizing outdoor space within the logistics park. Through product optimization and technical iteration, the prefabricated integrated cooling station has been continuously improved. Multiple containers are innovatively combined into a large integrated cooling station, breaking through the size limitations of traditional single-container designs.

The building is designed as a Class C factory structure, with one main floor and a partial second level. Inside the integrated cooling station, pumps, heat exchangers, and chiller modules are arranged on the first floor, while cooling towers are placed on the second. Twelve functional container modules are interconnected to form three system units, with maintenance routes inside the cooling source modules. Compared to Phases I and II, this design saves 40% of floor space.

Each container is fully equipped with insulation, ventilation, and air conditioning. The number of exhaust fans and airflow volume ensure five air changes per hour. Adjustable louvers prevent air exchange in winter, reducing heat loss. External rain covers and insect screens provide weather and pest resistance. The design targeted a PUE of <1.25, and actual operation shows even better performance under low-load conditions, demonstrating outstanding energy efficiency and system optimization.

Setting a New Industry Benchmark

Phase III increases single-unit cooling capacity from 1,300RT to 2,200RT, setting a new record for the world’s largest prefabricated integrated cooling station. Pre-assembled and tested off-site, the station was delivered in modular containers, installed on-site within 20 hours, with cooling towers simply lifted and connected. Internal piping, cable trays, and electrical work were completed within two weeks, ready for water and power connection. Compared to earlier phases, installation time was reduced by 16 hours, and overall project delivery time shortened by over 30%.

This project exemplifies a new industry paradigm that balances efficiency and energy savings through prefabricated construction, intelligent operation, and ultra-low PUE. It is not only a successful demonstration of integrated technology but also a strong response to the future needs of "rapid deployment and green operation" in data centers.

The innovative "multi-container spliced cooling station solution" overcomes physical space constraints inside traditional prefabricated containers, enabling N+1 redundant operation of larger-capacity chillers (2,200RT). This achieves dual breakthroughs in system capacity and delivery speed, significantly improving reliability and marking a major leap from skid-mounted prefabrication to containerized integrated cooling stations.

The seamless multi-container design fully leverages the spatial potential of logistics park renovations, ensuring high availability while substantially shortening construction timelines. It provides a successful model for the large-scale application of prefabrication technology and pioneers a new path for efficient, rapid, and high-quality construction of hyperscale data centers.

Leading the Industry Toward a Greener Future

This evolution signifies that prefabricated integrated cooling station solutions have progressed from pilot trials to a core approach supporting green, low-carbon data center construction. It demonstrates the comprehensive advantages of prefabrication in reliability, energy efficiency, and construction speed, while offering a complete solution for rapid deployment of high-power-density data centers. The project holds important exemplary value in promoting standardization, intelligence, and sustainability across the industry.

While enhancing overall energy efficiency, Phase III also maintains high reliability and green operation. It has been selected as a "2023–2024 High-Quality Energy Conservation and Emission Reduction Case in Computing Centers" and recognized by CDCC as one of the "Top Ten Outstanding Data Center Projects of 2025."

GLP's Southeast Data Center is built to the national Class A standard, providing leading data support for global financial, insurance, internet, government, and hyperscale clients. Its three phases offer a total of 120MW of IT load and 8,178 server racks.

GLP's global data center network spans 2,900MW, with 12 operational sites delivering over 320MW of IT load. Through its flexible, efficient, and low-carbon intelligent computing solutions, GLP has become a leading green computing infrastructure provider and was named one of China's top ten computing center service providers in 2024.

Address: Changshu, Jiangsu Province